Modeling

Developing experimentally validated thermal and structural models to run simulations to predict the behavior of railroad rolling stock and suspension elements under normal and abnormal operating conditions is one of the main strengths of the UTPA Railroad Research Group. The work performed by the research group has been published in several high impact engineering journals and railroad conferences, and has resulted in the creation of numerous master's theses.

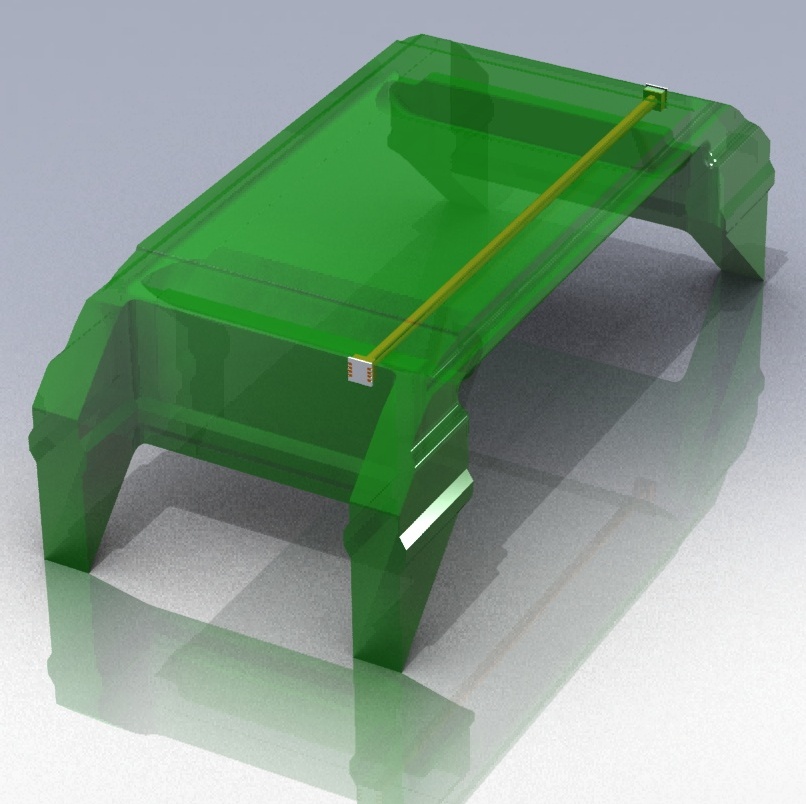

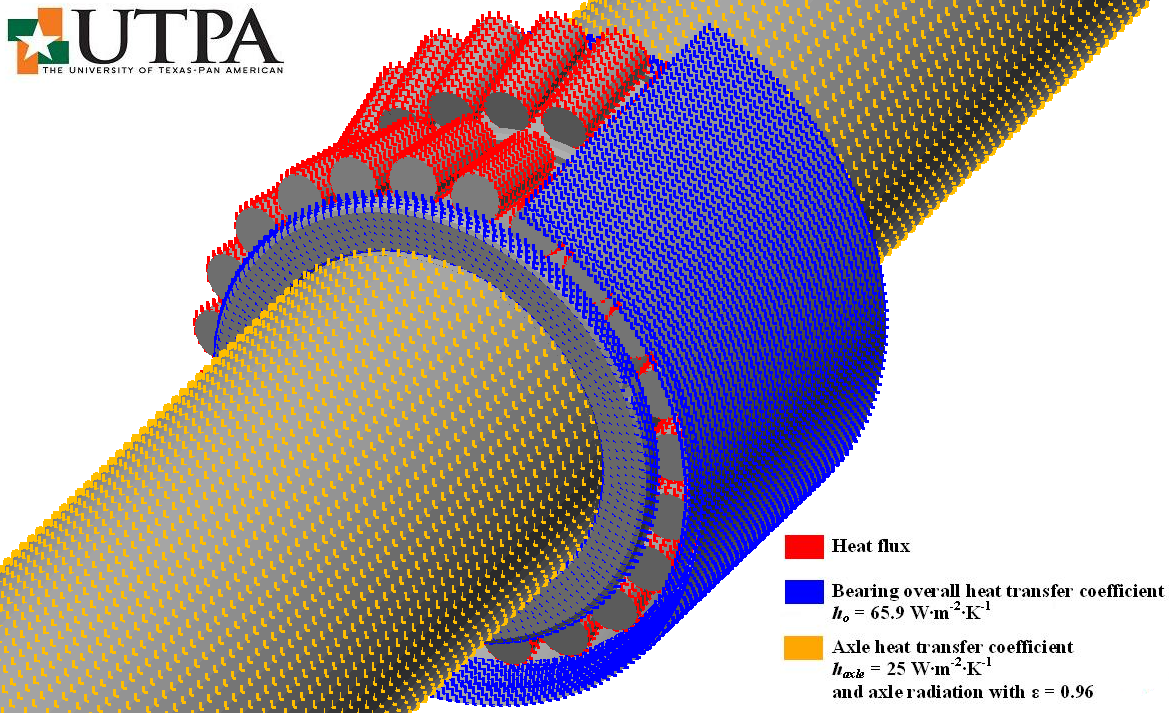

The modeling process starts with the generation of 3D CAD models that accurately mimic the components to be studied. Carefully planned laboratory experiments are then setup and run to collect data that can assist in the development, assessment, optimization, and validation of the devised theoretical and numerical simulation models. Since its inception, the UTPA Railroad Research Group has conducted extensive testing and modeling to identify and quantify the different heat transfer paths within the rolling-stock components and the suspension elements. Illustrative examples of such work are shown here.

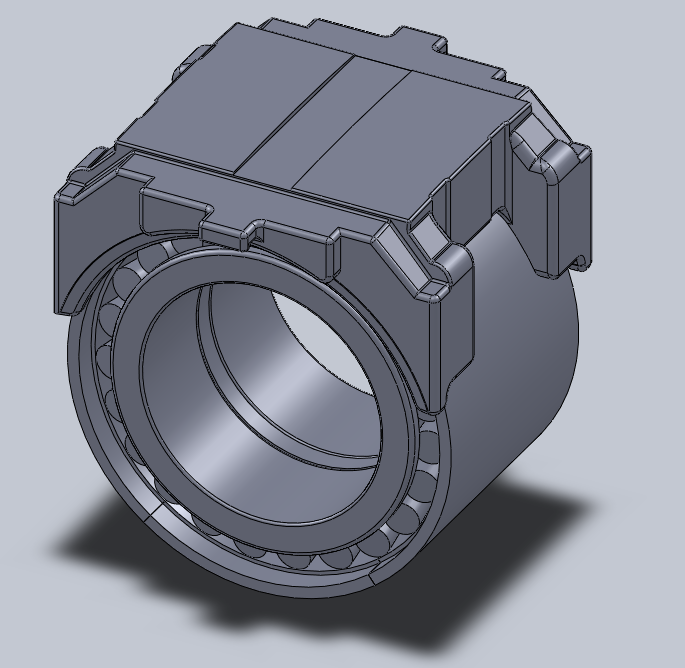

Bearing Heat Transfer

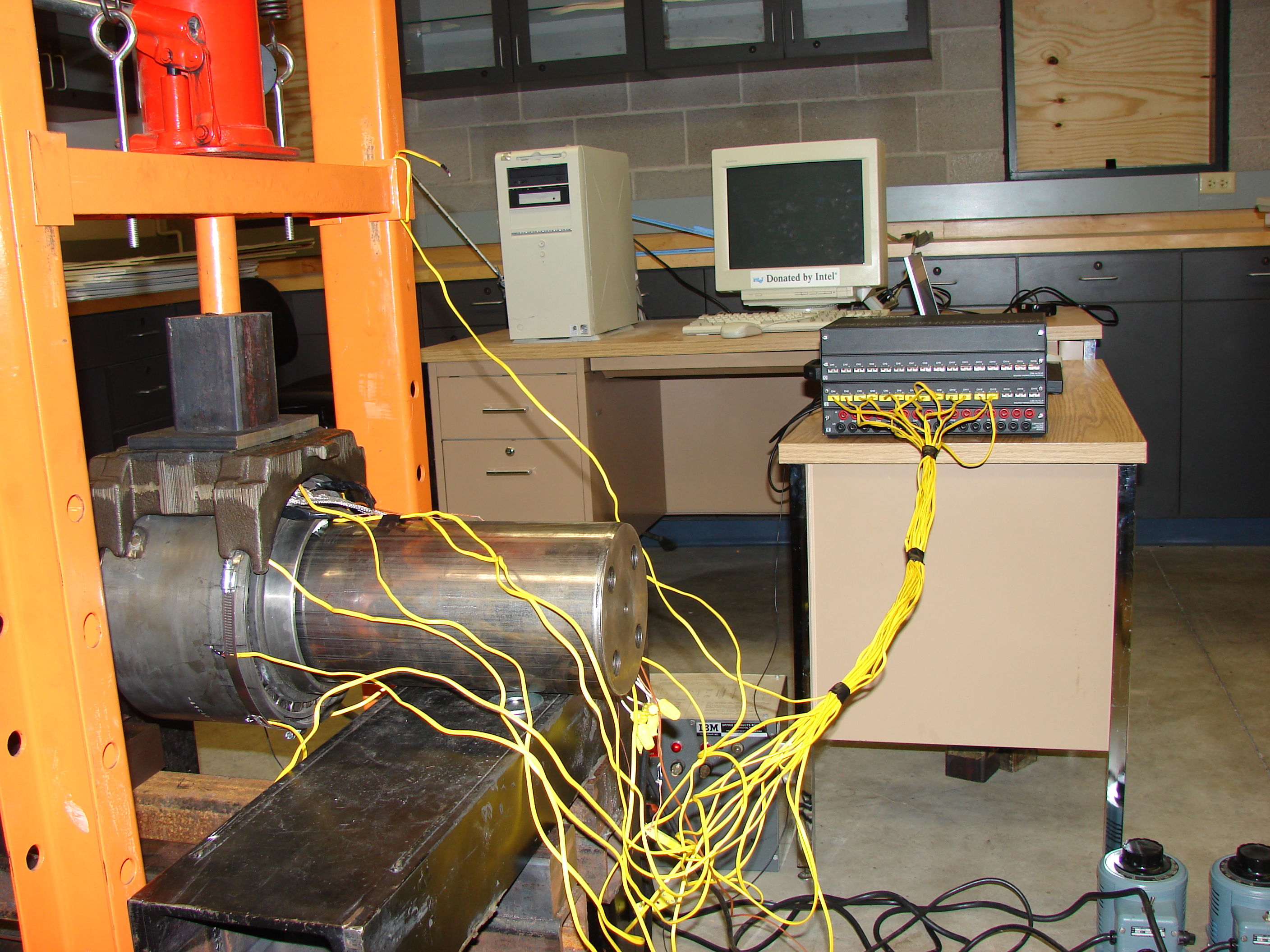

Early work conducted in the area of modeling focused on exploring the heat transfer paths within railroad tapered-roller bearings. Laboratory experiments were carried out utilizing a static test rig and cylindrical cartridge heaters embedded in several rollers within the cone assemblies. Theoretical and numerical (Finite Element Analysis - FEA) models were then constructed and compared to the experimentally acquired data to assess the validity of the models and their efficacy in predicting the thermal behavior of railroad tapered-roller bearings. The results of this study have been presented in a number of railroad conferences and published in a number of high impact journals in the engineering field.

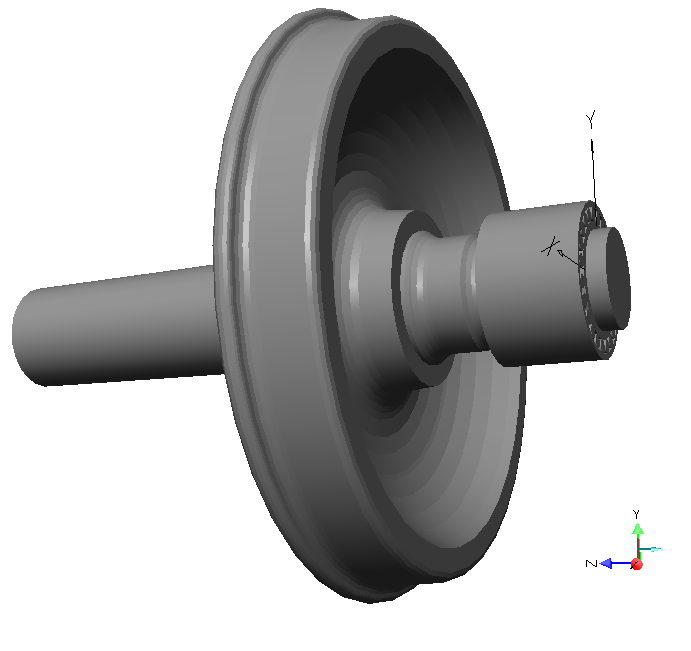

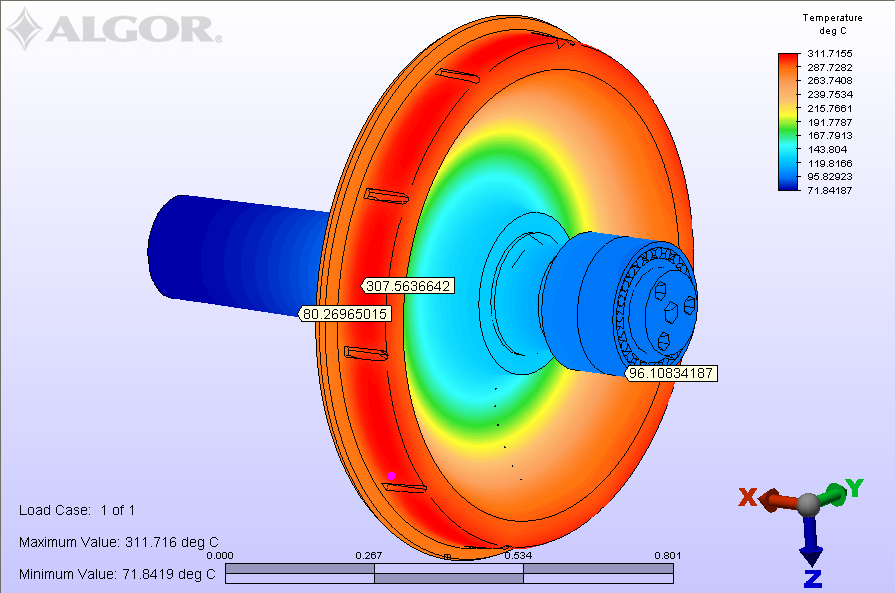

Wheel Heat Transfer

As a follow-up to the railroad bearing modeling study, experimentally validated theoretical and numerical (FEA) models were devised to simulate and quantify the heat transfer from a railroad wheel under normal and abnormal operating conditions. The study was conducted with the main objective of exploring the effects of wheel heating on the thermal behavior of the neighboring railroad bearing. Again, the results of this study were presented in railroad conferences and published in relevant engineering journals and conference proceedings.