Materials Laboratories

The materials laboratories at UTRGV are outfitted with a broad range of materials testing and characterization instrumentation. Available equipment and experience with local and national industry partners largely fall into three categories: (1) the laboratory has broad mechanical testing capabilities, (2) can perform sample analysis via optical and electron instruments, and (3) has a full suite of thermal analysis tools. The range of capabilities available under one-roof is rare and makes possible more rapid execution of projects requiring a variety of resources.

Thermal Analysis of Materials

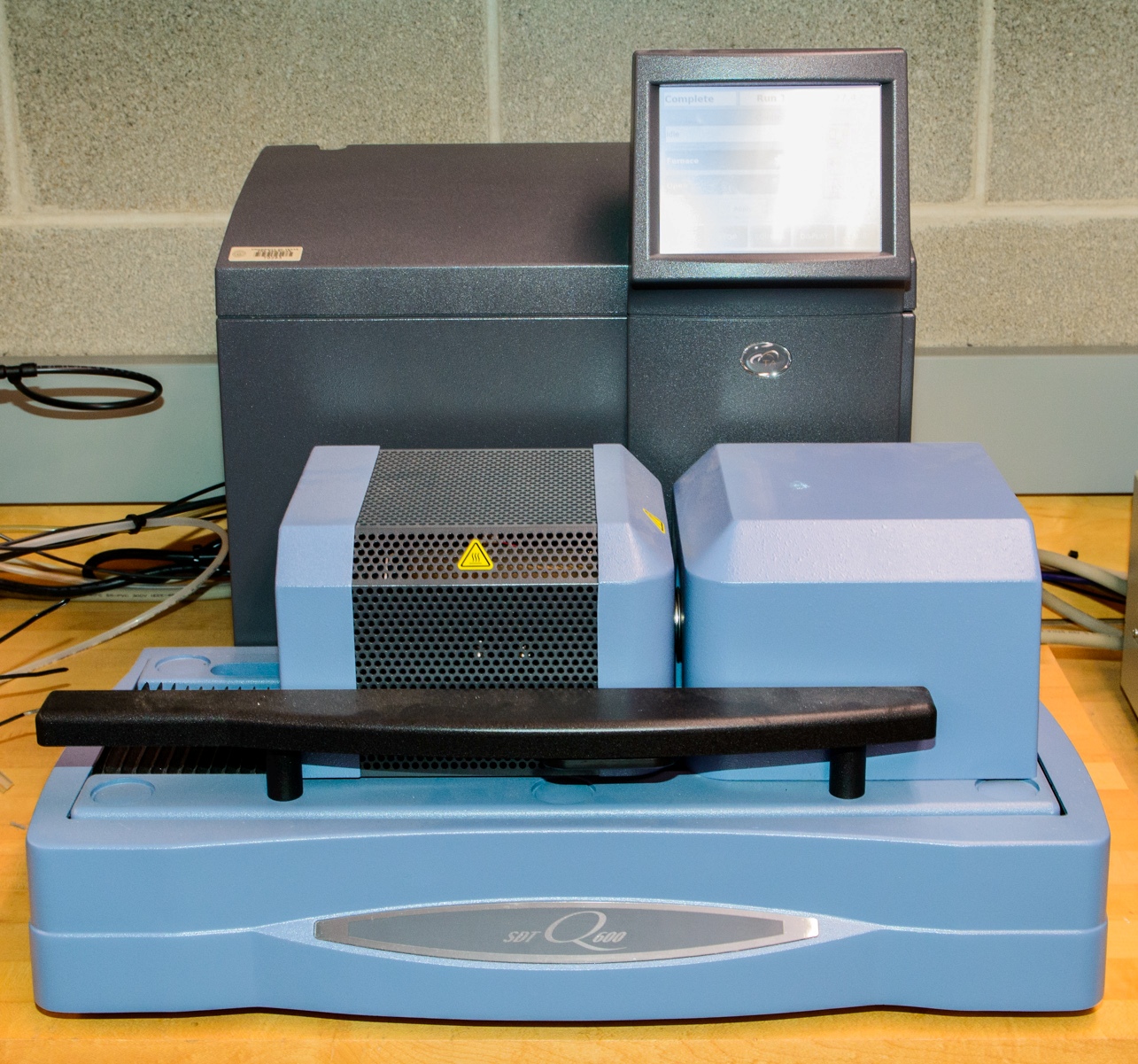

One of the greatest strengths of the materials laboratory lies in the breadth and depth of materials characterization via thermal analysis which can be performed in one location. We are equipped with a full suite of TA Instruments brand thermal analysis units, including Q-series Differential Scanning Calorimeter (DSC), Combined DSC and Thermo-gravimetric Analyzer (DSC/TGA), and a Dynamic Mechanical Analyzer (DMA). From the older generation of 2000 series instruments, there are a Thermo-mechanical Analyzer (TMA) and a Dielectric Thermal Analyzer (DETA). An older version of the DSC and DMA are also available if samples require either less precision or more care due to possible damage to the instruments. All of these instruments operate on the principle that a property of interest is continually measured while the temperature of the small sample is varied over a user specified range.

The DSC measures heat capacity of a sample and can detect phase changes, chemical reactions, and structural transitions. Because these behaviors are often sensitive to composition changes, thermal and chemical exposure, or simple age, the DSC is a powerful tool for detecting these factors. Its primary use is with organic materials such as plastics, composites, paints, adhesives, and lubricants. The DSC/TGA adds the ability to monitor specimen weight while heating, and is capable of thermal excursions well above 1000ºC (1832ºF). The combination makes it ideally suited to study decomposition of materials or other reactions which involve a change in mass of the sample. Samples can be run in air or an inert gas.

Mechanical properties can be evaluated by the DMA which will apply either step or cyclic loads or displacements to small samples of material while measuring mechanical properties over the test temperature range. It is widely used for characterizing polymer and polymer composite materials and makes possible rapid development of both dynamic response and creep models of material behavior. Testing is possible in several loading modes including three point bend, cantilever (single and double), and compression.

Finally the TMA measures thermal expansion with temperature and the DETA allows detailed characterization of the dielectric properties of a sample as a function of temperature and frequency. It is highly unusual for a single laboratory to be so well-equipped, and these instruments are usually widely scattered on a campus if they are even all available.

Sample Microscopy

The heart of the imaging capability in the materials laboratory is an ASPEX instruments PSEM scanning electron microscope, which is designed for work on components or large samples. The instrument is equipped with both secondary and backscatter detectors and has variable pressure (environmental SEM) so that non-conductive samples can be imaged without coating. The instrument operates comfortably at magnifications up to 50,000x. It also has energy dispersive x-ray analysis capability which provides qualitative compositional analysis with interpolated semi-quantitative analysis where reference samples are available.

If higher magnification work is required, a research grade SEM and an atomic force microscope are available in the microscopy laboratory associated with the nano-materials facilities in the College of Engineering and Computer Science. Optical characterization is provided by a state of the art digital microscope with digital image stitching and 3-D image generation capabilities. Sample sectioning, mounting, and preparation include standard manual and automated polishing equipment, a large capacity diamond saw (slicer/dicer) for hard material sectioning, and standard wet cutting and grinding machines.